The complete set of obsolete waste treatment equipment we produce is mainly used for the sorting of obsolete domestic waste that has been landfilled in cities for many years, and it can also be used for waste sorting in new domestic waste concentration areas. This set of equipment can sort domestic waste into four major parts: combustibles, organic soil, recycled materials and stones. In the absence of advanced treatment equipment, use combustible material incineration, organic soil below 20m/m for landscaping, recycling of renewable materials (such as waste plastics for secondary plastics), and stones as building materials Simple methods such as treatment can achieve the goal of reducing, recycling, and harmless garbage, and allowing the land of the treated garbage pit to be used for urban construction or a pit for repeated burying of garbage.

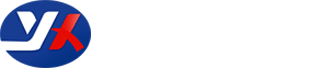

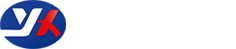

Stale waste treatment process plan:

The first step: excavation and transportation

The excavator digs out the stale garbage and loads it into the dump truck compartment, and transports it to the loading device of the screening equipment; for garbage dumps with a large slope, the transport trucks may have safety hazards to and from the stack, which can be transported by the excavator. Pile body work, transport materials from the pile body to the feeding device of the sorting equipment through the conveyor belt;

The second step: Feeding

Use loading equipment to load the stale into the feeder, and send it to the distributor evenly and in a limited amount, and separate the large-volume construction waste and other garbage that cannot be directly screened to reduce or avoid damage to the equipment.

The third step: manual sorting

The coarse bricks, pottery and other large pieces of garbage sorted by the distributor are selected by the manual sorting table to select the large pieces of fabric, rubber wheels, iron rods, etc., and other materials enter the drum screen.

The fourth step: drum screening

The stale garbage is divided into two parts: under-screen material and over-screen material by drum screening machine. The under-screen material is selected by a magnetic separator to select ferromagnetic material, and other materials become humus soil; the over-screen material is selected by a magnetic separator to select ferromagnetic material And other materials are transported to the comprehensive winnowing equipment.

The fifth step: Comprehensive winnowing

The on-screen material is separated from the light material under the action of the bulk roller screen and the fan with adjustable air volume and wind speed. The heavy materials are output by the output machine for building blocks; the light materials are compressed and transported and incinerated for power generation.

Four types of screening equipment:

Squirrel cage screen: screen out materials above 200m/m;

Roller screen: screen out materials below 40m/m, mainly organic soil:

Star screen: screen out organic soil below 20m/m for landscaping: 21-40m/m organic soil landfill:

Vibrating screen: Screen out rocks above 40m/m, etc.

Winnowing machine: specific gravity screening, screening out light materials such as plastic bags.