product description

Introduction to winnowing machine:Air Separator is usually divided into three types: positive pressure sorting, negative pressure sorting and combined positive and negative pressure sorting. Using the principle of aerodynamics, under the joint action of controllable positive pressure air flow and negative pressure air flow, the light and small substances in the material are separated from the heavy substances and enter the settling chamber, which separates the light substances from the air. Light materials are output through the light material discharging conveyor, and heavy materials are output through the heavy material discharging conveyor.

Sorting materials:

Light materials such as: plastic bags, woven bags, paper; heavy materials (mixed materials with large differences in density and specific gravity)

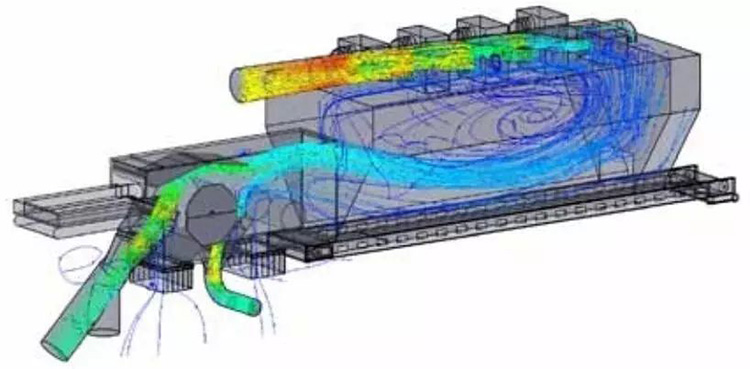

Schematic diagram of the working principle of light material air separation equipment:

This product is mainly composed of a box, a rack, an air supply system, a return air system, and a conveyor system. The air supply system and the return air system interact to form a regular air flow inside the box, driving the lighter material waste forward to the lower hopper of the conveying system. There are sealing plates and rubber guide grooves on both sides of the conveyor system, which can effectively prevent plastic products from wrapping around the rollers under the belt. The fan air inlet can be adjusted according to the material characteristics, which is highly flexible.

Actual pictures of winnowing machine products:

Equipment performance characteristics:

1. Negative pressure sorting, no dust leakage;

2. The wind speed can be adjusted steplessly to meet the needs of materials with different properties, including high-humidity materials;

3. Adopt modular design, good performance and low maintenance cost;

4. No need to configure wind system and filtration system (except for special requirements);

5. Choose the double-drum separated type, which can be divided into three components: light, medium and heavy;

6. Few wearing parts, extremely low downtime and maintenance time;

7. Integrated electronic control and mechanical design, plug and play at the installation site;